LOLER Compliance System

I designed and built a bespoke LOLER inspection and compliance management system for SG Handling, a forklift and materials handling company. The platform replaces paper-based inspections with a structured digital workflow that covers scheduling, on-site examinations, defect tracking and the generation of legally compliant certificates. The system is built as a practical operational tool rather than a generic web app. It focuses on reducing admin time for operatives, improving accuracy, and giving customers direct access to their inspection records and certificates. All documentation is produced in line with HSE GN28 guidance and meets the requirements of LOLER 1998 and PUWER 1998.

Industry: Materials Handling / Forklift Services

Project Type: Bespoke Web Application

Technologies: PHP 8.3, Laravel 11, MySQL, Tailwind CSS, Alpine.js, DomPDF

The Problem

SG Handling carries out LOLER thorough examinations as part of its servicing and compliance offering. Inspections were previously managed using paper forms and manual processes, which caused several ongoing issues:

- Operatives spent too long completing paperwork on site

- Certificate numbering and record keeping were manual and prone to error

- Customers had no simple way to access certificates or inspection history

- Repeating equipment data for every inspection wasted time

- Ensuring reports consistently met LOLER, PUWER and GN28 requirements relied heavily on individual judgement

The client needed a system built specifically around how LOLER inspections are actually carried out in the field, not a generic inspection app.

The Solution

I built a custom web-based platform designed around real workflows, with separate access for admins, operatives and customers.

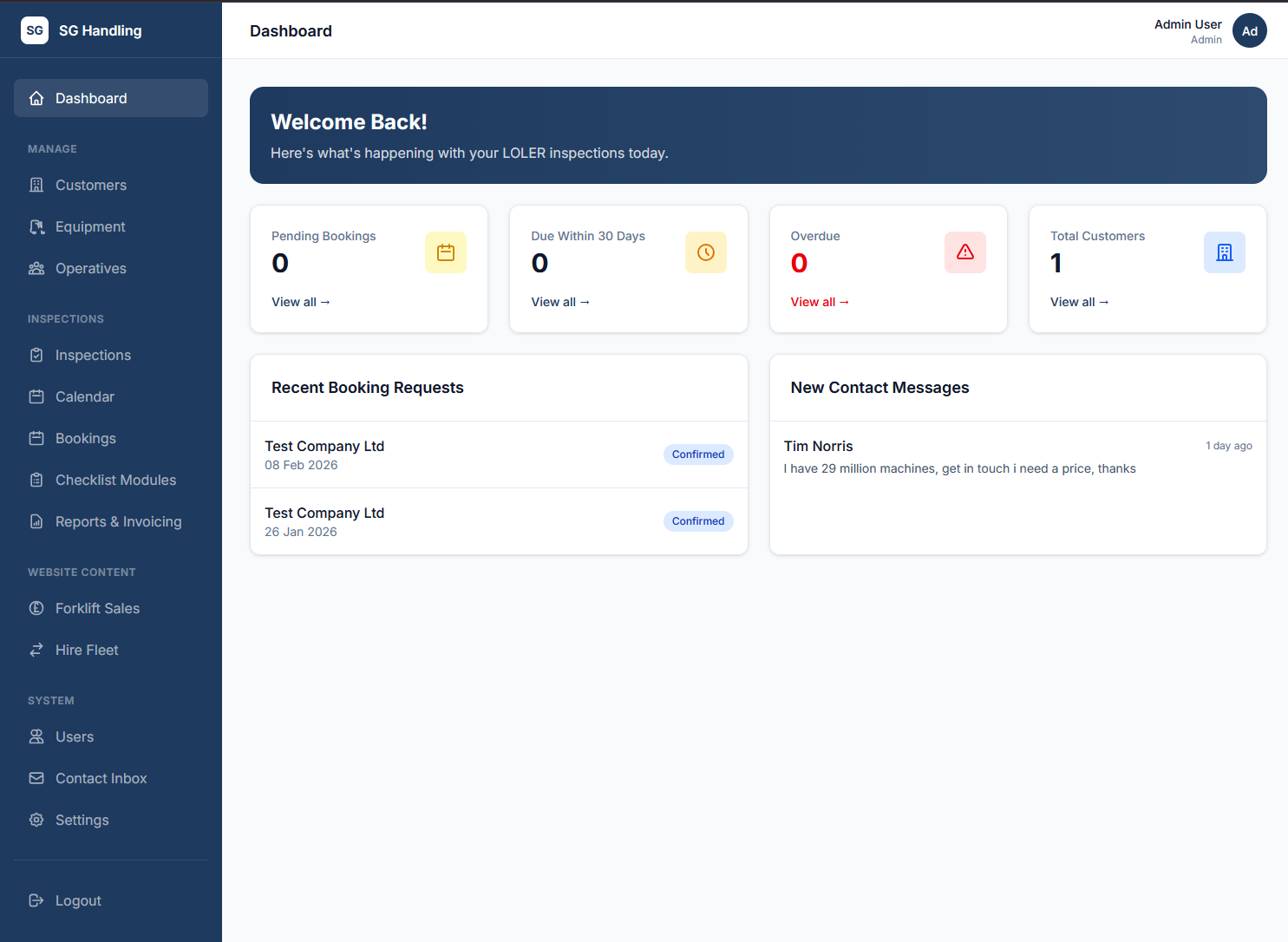

Admin Portal

The admin area provides full visibility and control of the inspection process:

- Management of customer companies and contacts

- Central register of all lifting equipment under contract

- Operative accounts and inspection assignments

- Inspection scheduling and oversight

- Status tracking for inspections due, completed and overdue

- Basic reporting and billing oversight

Operative Portal (Mobile-First)

The operative portal is designed for use on-site, on a phone or tablet:

- Clear daily inspection schedule with site details

- Digital GN28-based inspection forms

- Automatic pre-population of equipment details from previous inspections

- Defect logging with severity levels and GN28 references

- Outstanding defects carried forward to future inspections

- Dedicated fields for chain and fork wear measurements

- Examiner digital signature captured on completion

- Automatic calculation of next inspection due date based on frequency reasoning

The aim was to reduce repeat data entry while still allowing engineers to amend and record changes accurately.

Customer Portal

Customers have direct access to their inspection data without needing to request documents:

- Overview of all registered equipment

- Downloadable certificates and reports in PDF format

- Full inspection history for audit purposes

- Ability to request inspections and servicing

PDF Certificates and Reports

Producing compliant documentation was a core requirement. I created structured PDF templates for:

- Certificates of Thorough Examination

- Reports of Thorough Examination in GN28 format

- Inspection checklists

All PDFs include company branding, automatic certificate numbering, examiner details and digital signatures. The layout and content follow HSE GN28 guidance and LOLER Schedule 1 requirements.

Certificate numbers are generated automatically and increment sequentially to prevent duplication or gaps.

System Design

The database structure reflects how inspections work in practice:

- Companies linked to multiple items of equipment

- Equipment linked to repeated inspections over time

- Inspections linked to defects and checklist results

- Role-based access for admins, operatives and customers

- Configurable settings for branding and certificate numbering

This allows inspection history to be maintained cleanly across the lifecycle of each piece of equipment.

Results

The system delivered clear operational benefits:

- Inspection time reduced by around 40 percent

- Fewer errors caused by handwriting or duplicated data

- Certificates available instantly rather than posted or emailed later

- Consistent report formatting across all inspections

- Improved confidence that all statutory requirements are met

- A platform that can scale as the business grows

Conclusion

This project is a good example of how a purpose-built platform can replace paper-heavy processes with a system that actually supports how people work day to day. Rather than focusing on visuals alone, the priority was building a tool that solves operational problems, improves compliance and reduces friction for both operatives and customers.